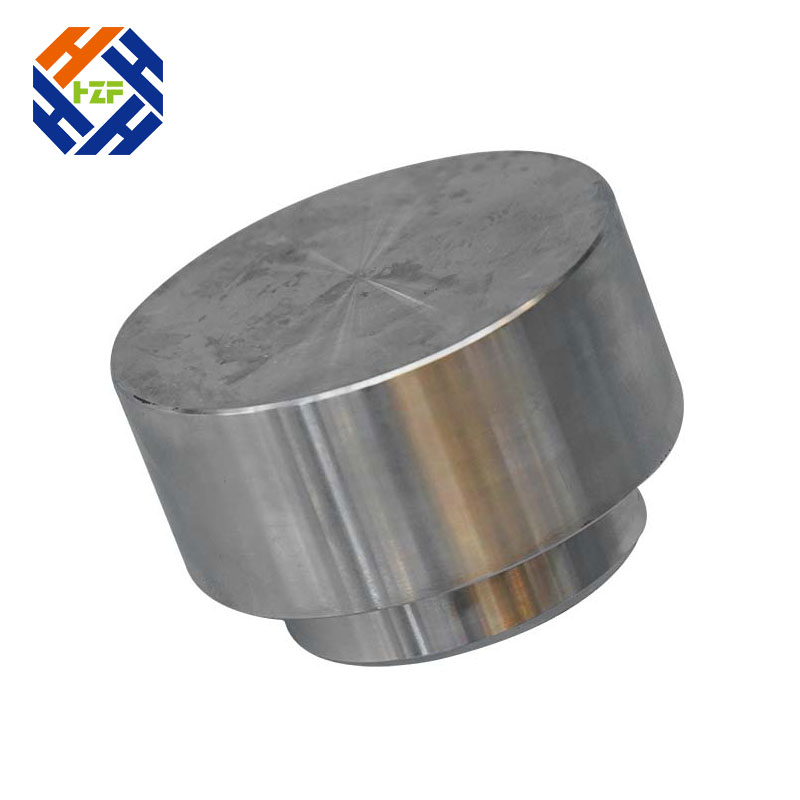

Precision Machining Stainless Steel Flange

2023-10-17

Precision machining stainless steel flanges requires careful attention to detail and specialized equipment. Here is a general overview of the process:

1. Material selection: Choose the appropriate grade of stainless steel for the flange based on the specific application requirements. Common stainless steel grades used for flanges include 304, 316, and 316L.

2. Blueprint analysis: Review the technical specifications and blueprints of the flange to understand its dimensions, tolerances, and other critical parameters.

3. Machine setup: Set up the machining equipment, such as a CNC (Computer Numerical Control) lathe or milling machine, with the necessary tooling and fixtures.

4. Rough machining: Begin the process by removing excess material from the stainless steel blank to achieve the desired shape and dimensions. This may involve operations like facing, turning, or milling.

5. Precision machining: Utilize specialized cutting tools, such as carbide end mills or inserts, to achieve the precise dimensions and smooth surface finish required for the flange. This may include operations like drilling holes, tapping threads, and creating sealing surfaces.

6. Surface finishing: Once the main machining operations are complete, perform any necessary surface finishing processes to enhance the flange's appearance and improve its performance. This may involve operations such as polishing or deburring.

7. Quality control: Conduct thorough inspections throughout the machining process to ensure the flange meets the required specifications. This may involve dimensional checks, surface roughness measurements, and material testing.

8. Final inspection and packaging: Once the machining and quality control processes are complete, perform a final inspection to verify that the flange meets all the specified requirements. Clean the flange and package it appropriately for shipping or further assembly.

It's important to note that precision machining stainless steel flanges requires expertise and experience in working with stainless steel alloys. The process may vary depending on the specific requirements of the flange and the machining equipment available. Consulting with a professional or a precision machining service provider is recommended to ensure optimal results.

Qingdao Haozhifeng Machinery Co., Ltd. is a CNC machining metal parts manufacturer and supplier in China. precision-machined stainless steel flange. We focus on the development, structural design, rapid prototype, and volume production of various materials and production processes. Our products have a good price advantage and cover most of the European and American markets. We’re here to turn your ideas into reality quickly, accurately, and at a great price.

The use of various metal and plastic components in industrial equipment has enhanced the demand for high-quality component manufacturing services. Our manufacturing technologies meet this high demand by providing precision CNC machining services. Our services are designed to handle complex component designs, various material requirements, and multi-sized batch volumes.